Circuits Central is your partner for printed circuit board assembly (PCBA) from the first prototype through full-scale production. Based in Toronto, we provide comprehensive PCBA services to clients across Canada – from coast to coast to coast – and throughout North America. Our decades of experience mean that we can handle everything from prototypes and low-volume runs to high-volume production across diverse industries while maintaining the quality and reliability your products demand.

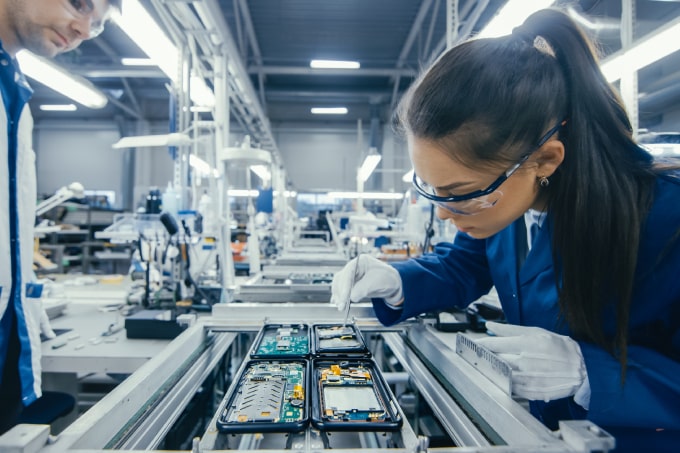

Modern electronics depend on flawless circuit boards. A well-assembled board ensures that your product performs as intended, meets regulatory requirements and reaches the market quickly. Whether you are developing a new product or upgrading an existing design, Circuits Central’s PCBA services bring together advanced equipment, skilled technicians and stringent quality processes to deliver boards that work the first time.

We offer a complete range of assembly services tailored to your needs:

Quality is paramount in PCB assembly. We follow industry best practices and apply IPC-A-610 workmanship standards appropriate to each build to ensure that every assembled board meets its performance and reliability requirements. Our quality-control methods include, but are not limited to:

Rapid prototyping accelerates product development. Our quick-turn assembly services produce prototype boards in as little as 24 hours. We accept small orders: there is no minimum order quantity and we provide DFM/DFT feedback so that prototypes translate smoothly to mass production. When you are ready for volume, our scalable production lines ensure consistent quality and on-time delivery.

Rapid prototyping accelerates product development. Our quick-turn assembly services produce prototype boards in as little as 24 hours. We accept small orders: there is no minimum order quantity and we provide DFM/DFT feedback so that prototypes translate smoothly to mass production. When you are ready for volume, our scalable production lines ensure consistent quality and on-time delivery.

Sourcing electronic components can be complex. Circuits Central’s procurement team manages the entire BOM:

Our collaboration doesn’t end at the assembly line. Circuits Central’s engineers work with you from the design phase through production:

Our PCBA capabilities support a wide range of applications, including:

While our facility is in Toronto, we serve clients nationwide and abroad. Partnering with a Canadian manufacturer offers several advantages:

Yes. We support prototypes and low-volume builds with no minimum order quantity. Quick-turn prototypes can be assembled within 24 hours, depending on component availability.

We need your Gerber or ODB++ files, BOM, and pick-and-place/centroid data. Assembly drawings or notes about critical components, special instructions and test requirements are also helpful.

Absolutely. We offer turnkey services where we procure all parts. If a part becomes obsolete or unavailable, we will recommend equivalent substitutes and obtain your approval.

Components can be provided in trays or bags, marked with part numbers from the BOM. We accept cut tapes with prior approval.

Yes, we support RoHS-compliant soldering, adhere to REACH guidelines for responsible chemical management, and offer leaded processes for legacy or industrial applications.

We follow IPC-A-610 workmanship standards suited to your project and employ AOI, X-ray inspection, ICT, functional tests and temperature-cycling stress screening to detect defects before shipment.

Yes. We manage engineering change orders efficiently, update documentation and adjust assembly processes to incorporate new revisions without disrupting production.

If you are looking for a reliable PCBA partner to assemble prototypes or scale up to high-volume production, Circuits Central is ready to help. Contact us today to request a quote or learn more about our services. Our team is committed to bringing your ideas to life with precision, speed and uncompromising quality.

Not ready for PCB assembly yet? Circuits Central can help you move from concept to prototype with our comprehensive electronic design services, including schematic development, PCB layout design, and rapid prototyping. We bridge the gap between your idea and a production-ready design.

Printed circuit boards (PCBs) are the small (typically green) chips covered in lines and copper….

To achieve a fully functional printed circuit board (PCB) product within a short timeframe, assembly….

Printed circuit boards (PCBs) are crucial in healthcare and medicine. As the industry continues to innovate…..

A fundamental component of any modern type of electronic device is a printed circuit……

Choose Circuits Central for Printed Circuit Board Assembly and experience:

Contact Circuits Central today for a consultation or quote tailored to your PCBA needs. Let us transform your designs into high-performance products.

Phone: (888) 602-7264 | Email: info@circuitscentral.com

Trustindex verifies that the original source of the review is Google. Excellent PCB assembly services. We have had an excellent experience with Circuits Central. - Turn Around Time: Boards were always assembled on time including expedited projects with 24-hour TAT. - Customer Service: Customer service is fast to respond over email and resolve any outstanding issues very quickly. - Quality: Excellent assembly quality with no errors or issues including for complex projects. - Communication: Circuits Central made the jobs simple to submit. We didn't have to submit many files or prepare every last detail for them.Posted onTrustindex verifies that the original source of the review is Google. Circuits Central has been making our boards for over 25 years. They are a great company to work with.Posted onTrustindex verifies that the original source of the review is Google. Great customer service! Highly recommend the team at CCIPosted onTrustindex verifies that the original source of the review is Google. I've been using Circuits Central for over 10 years for all of our NPI projects. Workmanship is exceptional and deliveries are always on time. Many thanks to the Circuits Central team.Posted onTrustindex verifies that the original source of the review is Google. Excellent service and printed circuit assembly quality for 6 years so far, at a very reasonable price. Highly recommended!Posted onTrustindex verifies that the original source of the review is Google. Tailored Service Levels and Pricing. Excellent quality!

Please fill out the form below and we will get in touch with you to further discuss your needs.