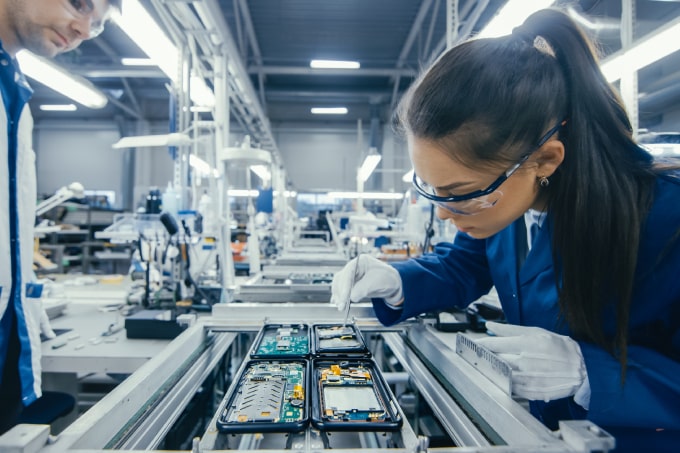

At Circuits Central, we are seasoned experts in electronics manufacturing and PCB assembly. Our clients gain access to a flexible-by-design and reliable production facility that delivers the confidence they expect for a range of production volumes and complexities.

By integrating our Electronics Manufacturing Solutions thought our clients’ product development, Circuits Central will handle all aspects of manufacturing – from Material Management, PCB Assembly, cable assembly, product testing and integration.

Circuit Central’s Research & Development team is constantly reviewing and improving our operation and quality control techniques as a way to surpass customer demands.

New processes are developed to tackle PCB assembly challenges of cutting-edge electronics. We let our record speak for itself – we have guided our clients through the entire process, no matter how intricate their design is. That way, they will have the knowledge necessary to be competitive in a global market.

Please provide the following information for a quotation:

Yes, we check BOM and share available components, helping reduce manufacturing costs.

The process involves order confirmation, component and circuit board ordering, stencil application, assembly, quality check, and shipping.

Yes, we offer Turnkey, Partial Turnkey, and Kitted/Consigned PCB assembly. Ship the parts to our facility in Markham, ON, following the BOM and quoting information.

Components can be provided in trays or bags, marked with part numbers from the BOM. We accept cut tapes with prior approval.

Standard Testing includes:

Visual Inspection

AOI Inspection

Solder Paste Inspection (during print and post production)

X-Ray inspection (for BGA’s and fine-pitch parts)

Functional testing (if required by the customer)

Environmental Stress Tests (if required by the customer)

Yes, we offer conformal coating as part of our PCBA services.

Yes, we offer RoHS-compliant assemblies.

We accept credit cards, wire transfers, and checks. After you approve our quote, please send a purchase order or provide payment information, and we will start processing your order.

For the first order, pre-payment is required. Payment terms can be extended on approved credit. Credit card payments and wire transfers are accepted.

Printed circuit boards (PCBs) are the small (typically green) chips covered in lines and copper….

To achieve a fully functional printed circuit board (PCB) product within a short timeframe, assembly….

Printed circuit boards (PCBs) are crucial in healthcare and medicine. As the industry continues to innovate…..

A fundamental component of any modern type of electronic device is a printed circuit……

Please fill out the form below and we will get in touch with you to further discuss your needs.