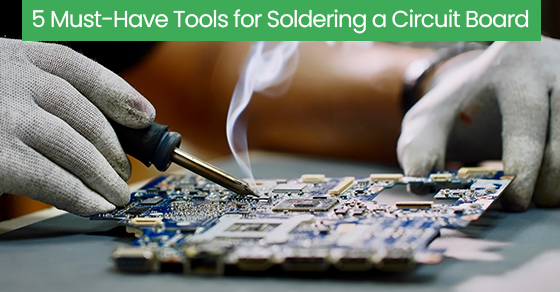

5 Must-Have Tools for Soldering a Circuit Board

In the world of electronics manufacturing, soldering is one of the most essential processes, and that is especially true when it comes to the manufacturing of circuit boards.

Soldering is an intricate procedure that involves joining two materials without fusing them. Whereas welding melts metals to fuse them, soldering works by melting a filler material made of a metal alloy called solder and using it to forge a connection.

Since soldering makes creating strong and reliable electrical connections possible, it is most commonly used to join electrical components to a circuit board. First, the solder must be heated to an extremely high temperature with an iron set between 316° and 343°C. Then, it is applied to the metal parts that must be connected. When the solder cools, it bonds to the metal and forms a connection.

What are some of the essential tools that you should have for soldering circuit boards?

Using all the right tools when soldering on a circuit board would be best. After all, a circuit board’s components are often small and complex, and if you want to avoid problems with your finished circuit board, employing the right tools is the only way to do that.

The following are some of the essential tools that you should have access to when you are preparing to solder a circuit board:

1. A Pencil Soldering Iron

Without a soldering iron, soldering is simply impossible, so it is undoubtedly one of the first tools you should get your hands on if you need to solder a circuit board. When you use a soldering iron, its tip heats up, and you put this tip on the soldering wire to melt it down and forge a joint on the circuit board.

Soldering irons can come with a variety of different tip shapes, which are designed for use in various specific applications.

However, the best and most common tip for your soldering iron is the pencil type, which is from its pencil-like appearance. The sleek design of this tip makes it easier to use in a wider variety of ways, including for the soldering of finer detailed areas and components.

2. A Soldering Station

When you solder a circuit board, it is frequently necessary to use a variety of temperature values for different specific components.

If you have a solo soldering iron, this will not be possible, as it will have a fixed temperature value; however, it is possible to adjust the temperature value of your iron if you have a soldering station. A good soldering station can help improve your soldering process in various ways.

A soldering station typically has a stand where you can place your soldering iron when you are not using it. The soldering plugs into the station itself, allowing you to adjust the iron’s temperature as needed and per varied circuit requirements.

3. Circuit Holding Hands

When you are soldering a circuit board, it is vital that it is stable during this process to ensure your work is exact. An excellent tool to help with this is circuit holding hands, as these clips will hold your circuit board in place.

You can even attach an LED light or a magnifying glass to one of your helping hands to make it easier to see what you are doing during the soldering process, minimizing your chances of making unnecessary errors.

4. A Soldering Fume Extractor Unit

During the soldering process, it is natural to generate smoke as the solder is melted and connections are made on the circuit board.

If you will be soldering for a considerable amount of time and you are working in an environment with limited circulation, your lungs could be exposed to too much smoke, which is toxic to your health, which is why it is crucial that you make use of an excellent smouldering extraction unit.

A soldering fume extractor will absorb all the harmful smoke generated and filter it to remove the toxic components so that you can continue to breathe fresh air.

Although a soldering fume extractor unit is a must-have for smaller enclosed working spaces, you can settle for a decent soldering fan if you have a large and open workspace.

5. A Desoldering Station and Gun

Although soldering mainly involves forming closed connections between components on a circuit board, occasionally, you may need to reopen these connections.

For instance, if you notice that you have made a mistake during your soldering process or detect a bad component in the circuit and need to remove it, such desoldering will be necessary.

In these types of scenarios, you will be required for you to use a desoldering station and gun. A desoldering station and gun are quite similar to a soldering station and gun, with the main difference being that the gun sucks in the solder after melting it down, leaving you with a clean, open connection.

How Circuits Central Can Help with All of Your Circuit Board Soldering Needs

If you have any concerns about soldering circuit boards, it is okay; it is not necessary to do it all on your own. You may be better off entrusting the soldering and the rest of the PCB manufacturing process to experienced professionals like our team at Circuits Central.

We have the know-how, the tools, and the expertise to help you assemble some top-quality PCBs, and we can make the entire process smooth and seamless for you.

We can help during the designing, prototyping, or testing phases as well, as our services are fully comprehensive, and we can help with as much or as little as you would like. We are constantly focusing on quality control to ensure that every customer leaves with the utmost satisfaction, and we will dedicate the same attention to detail to any projects we take. Let us help you create a superior product that will exceed your expectations.

For more information about our approach to soldering circuit boards or how we can help you produce top-quality PCBs, call Circuits Central at 1 (888) 602-7264 or email us at info@circuits-central.com.